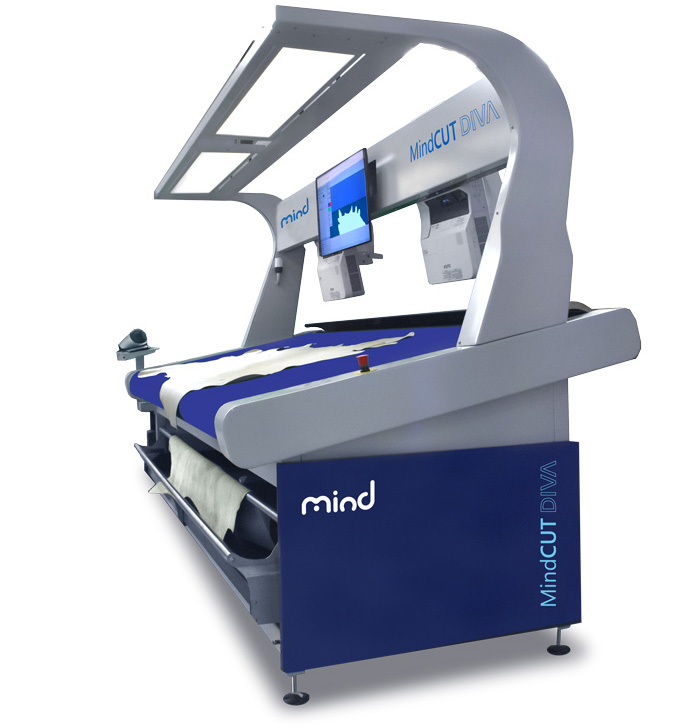

DIVA stands for Digital Inspection and Virtual Annotation. It is a piece of hardware, conceived and designed by Mind and produced by a highly specialized Portuguese partner, which combined with software is suitable for any industry where there is a need to automatically digitize contours of heterogeneous and/or irregular shapes like for instance leather and manually and with the manual non destructively annotate defects.

DIVA unit is now sold in two different versions corresponding to two different workspace areas. The larger model is adequate to production using larger materials.

The non-physical marking is a totally non-destructive marking process that preserves the high quality of the material being processed and one of the key advantages of this product. The fact that this marking can be done offline (independent of the flow of production) enables better productivity and better exploitation of the cutting machine time. The continuous conveyor feed and capture process really enhances the operator productivity and comfort, as well as it fosters the precision and control of the digitalization process.

In order to have further information please check our site or just watch this video.