MindCAD 2D Modelling V5 release offers the following new features and enhancements:

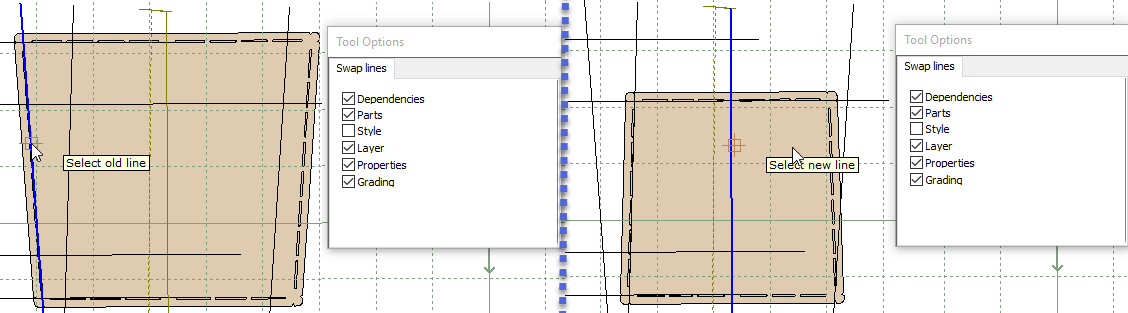

New behavior in Swap lines tool

Line replacement functionality was revised for better usability and to reduce modeling time taking in account identified typical operator patterns:

• Allows to swap several lines and axis without exiting the tool.

• Ability to preserve previously assigned contexts by choice.

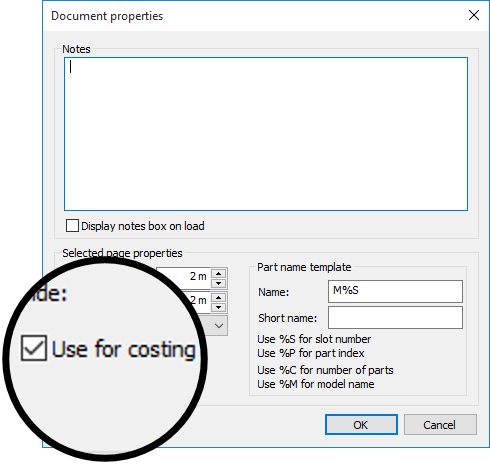

Ability to exclude sheets from consumption studies of Cost Evaluation

It’s now possible to define for each page in the document properties if it should be used or not for costing purposes.

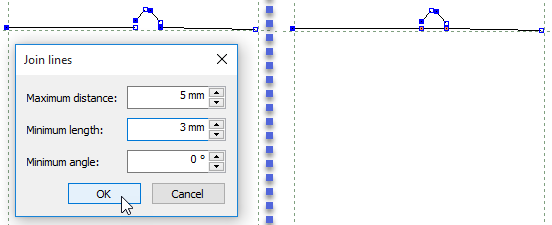

Extra control parameters in join lines by distance

To better filter the lines to join it’s now possible to choose a minimum length for the line to be consider and a minimum angle between the lines to join. This is very important to exclude notch geometry from the merging process.

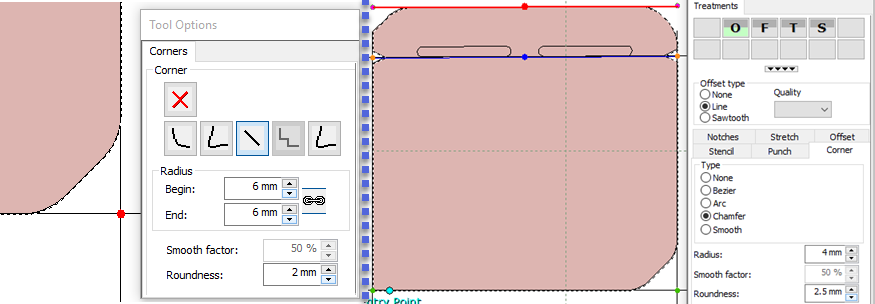

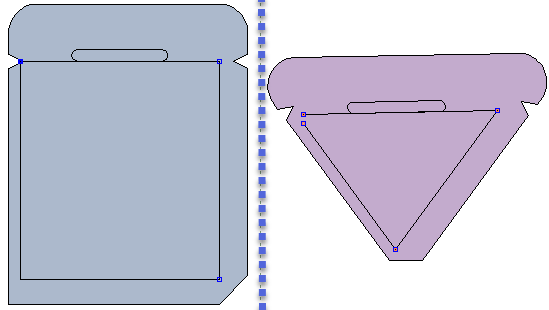

Ability to add corners to chamfer corner type

It’s now possible to add a roundness factor to chamfer corners. Can also be applied to chamfer corners in treatments. This have an impact on cut efficiency avoiding constant knife tool lifts.

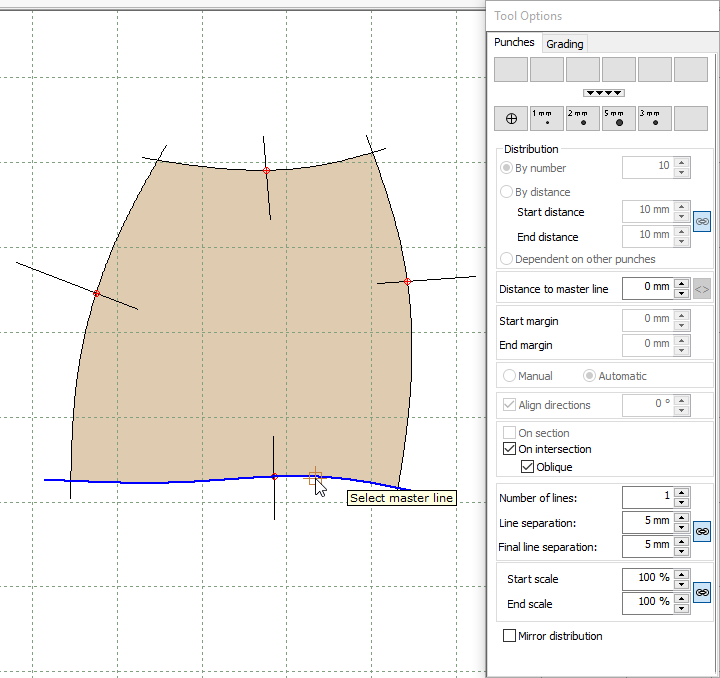

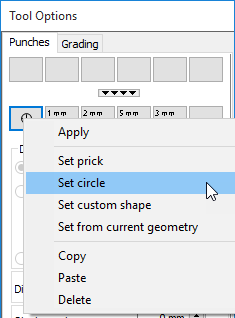

Punches tool optimizations

Punch functionality was revised for better usability and better integration with cutting software:

• Ability to quickly add punches to intersections, through new context option Finish and Repeat.

• No need to previously select a line to active the tool.

• Punch configuration panel redesign to include template customization for quick assignment. This is a necessary change to enable a new best practice to explicitly assign the correct punch dimension for automatic punch validation to occur in MindCUT Studio Production. Without this configuration, it will be machine operator responsibility to validate every model specification against installed punch bits. This procedure should replace older identification approach based on properties.

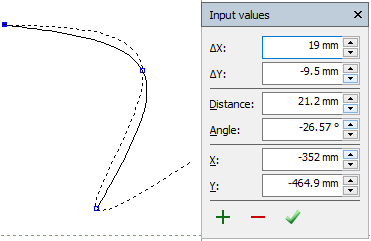

New approach when creating lines by coordinates

On the direction of a more intuitive parametric editing, creation of lines was revised to include some operator requests:

• Control where the next line handle will be placed using relative, polar or absolute values.

• Preview of the result of adding the handle at the specified position

• Possibility to place as many points as desired without exiting the tool.

Digitizing optimization

It is now possible to progressively remove previous digitized point by key accelerator.

Possibility to add different treatments to sub-paths of the base line

Auto-detection of corner points on part boundaries for treatments, independent of line base types. This remove some critical restrictions related to usage of closed shapes and provide a common consistent approach on the identification of candidate treatment segments.

It also has a dramatic impact on the workflow around imported geometry by removing the need of active line cutting to artificially create segments to be targeted by treatments.

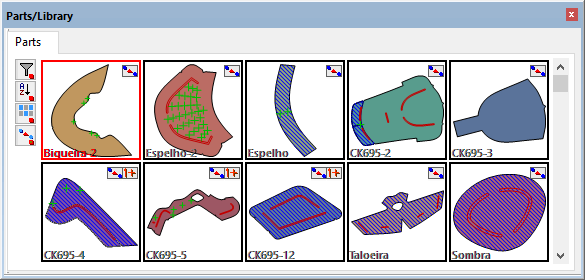

Parts bar thumbnails enhancements and visuals

• Part reference points are not hidden by labels.

• Part thumbnails shown in parts bar are now resized to fit the available space. The way the thumbnails are shown will vary depending if the parts bar is free or docked (vertically or horizontally).

The thumbnails were improved to better represent parts with quality areas.