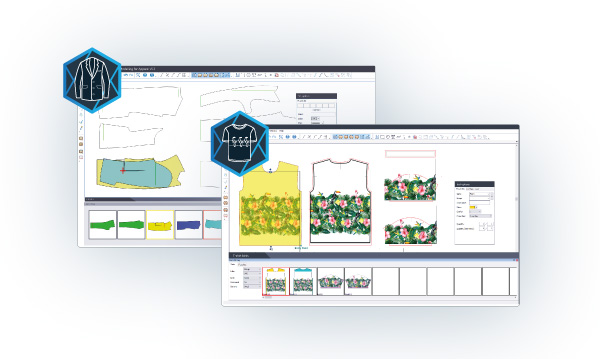

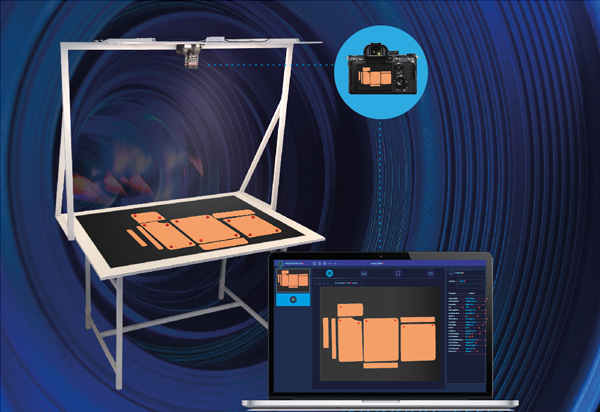

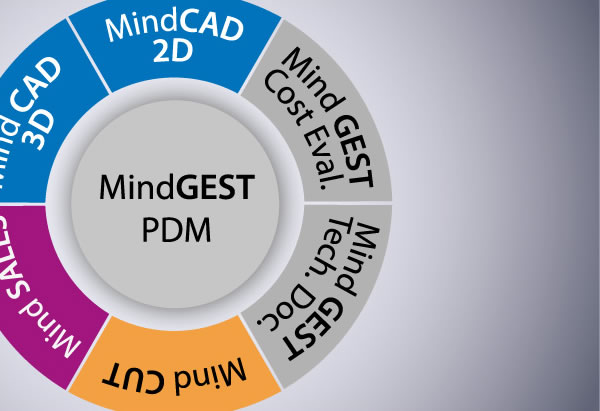

Accelerate and optimize the cut workflow

The best solution for cut preparation in Textile Print & Cut and Pattern Matching Scenarios.

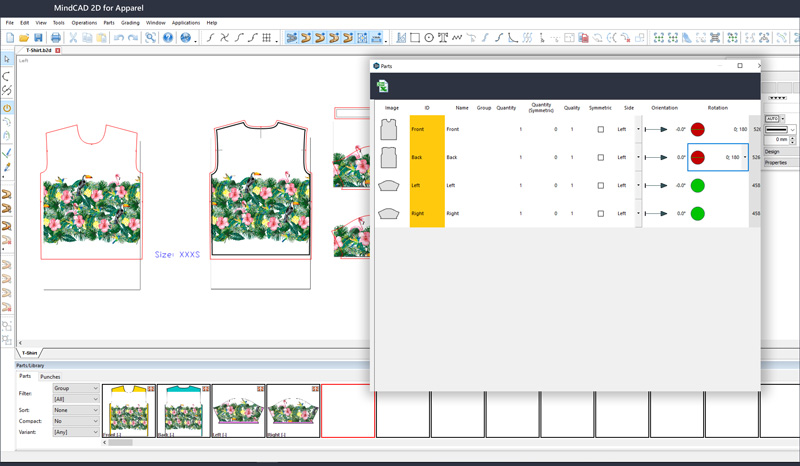

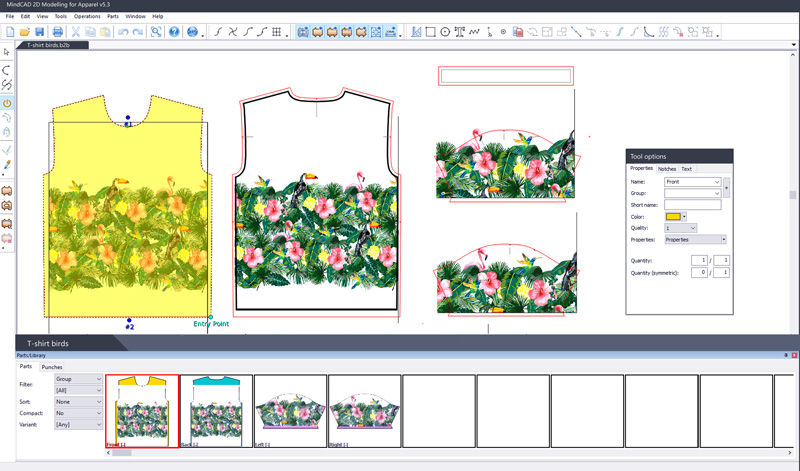

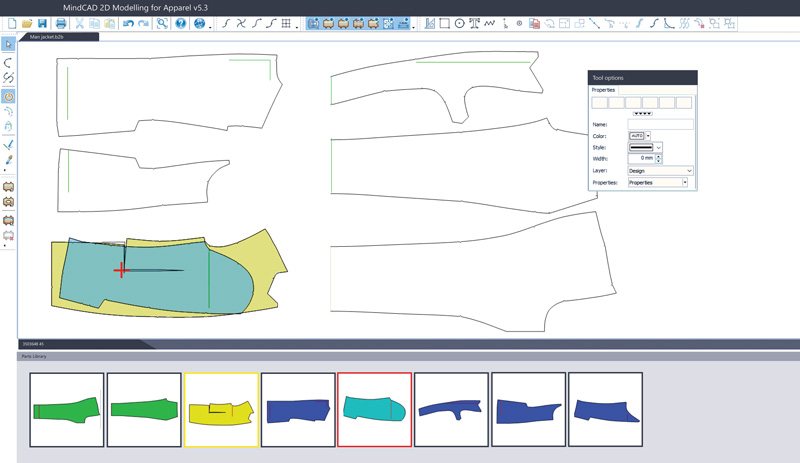

An integrated 2D environment for the design and engineering of Apparel models, focused on the preparation of parts to be cut in digitally printed materials and patterned textiles.