Mind Technology

Creative Solutions for Your Industry

Mind Technology

Creative Solutions for Your Industry

Select your language

Agility

Flexibly define your nesting scenarios.

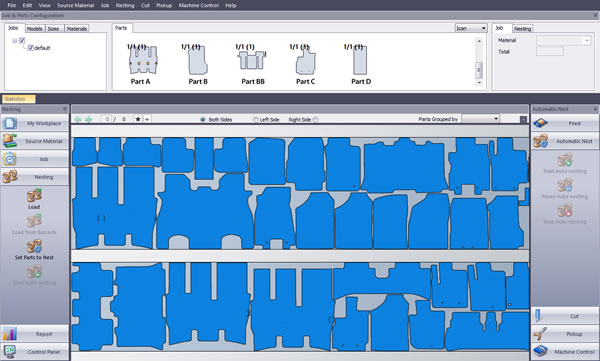

Handle simple or highly irregular patterns in complex synthetic materials with complex textures, and preferred orientations.

Nest on an unlimited number of materials, with large or small areas.

Quality on time

Save the time you now spend on nesting manually.

Nest the most complex pattern layouts and reduce the time it takes to produce high quality samples or graded patterns.

Cost reduction

Reduce raw material consumption and waste by producing cost effective layouts.

Automatic Nesting for Synthetics features

-

Optimal nesting

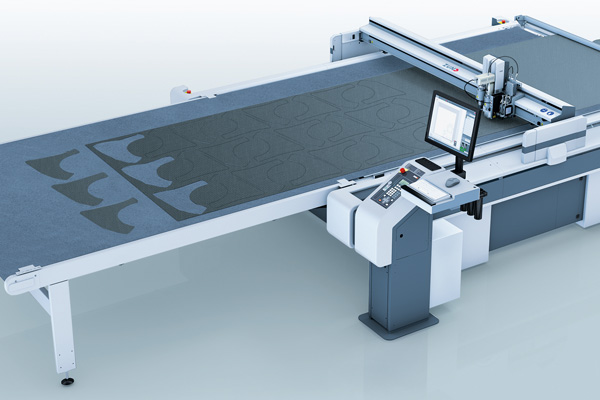

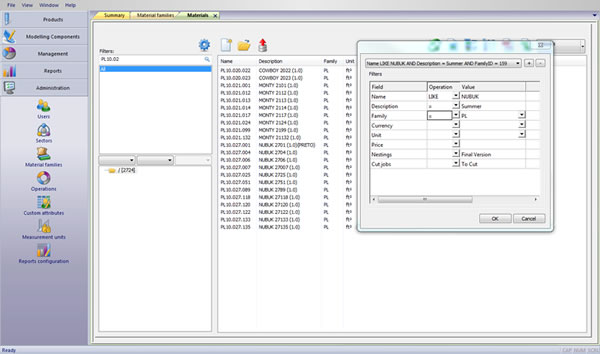

Advanced and specialized automatic nesting algorithms for synthetic materials, combined with interactive tools, for optimized results.

Preparation of nesting orders for multiple materials, including “infinite” roll materials or sheet materials.

-

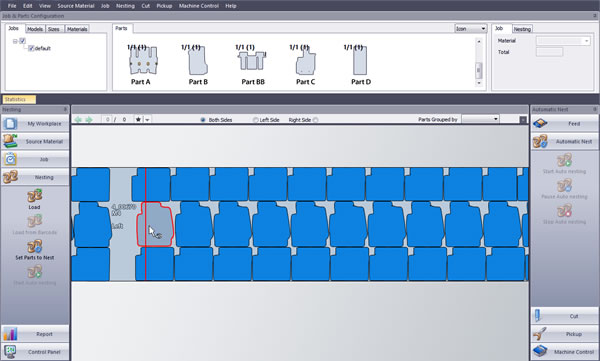

Dual nesting mode

Flexible methodology allowing mixed nesting interaction modalities.

Easily alternate between the interactive placement of parts and automatic nesting using controlled sets for the remaining parts.

-

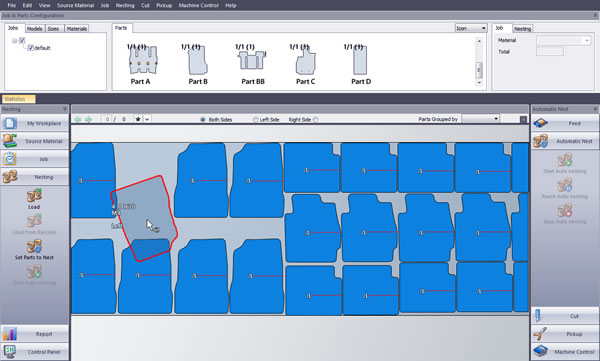

Precision and performance

The nesting algorithm respects predefined constraints, such as spatial orientation of the material and patterns, or material boundaries.

Optimized for precision and speed, ensuring the best outcomes and performance.

-

Integration

Import models from MindCAD 2D Modelling or other third party CAD solutions.

Publish the nesting results into the MindGEST PDM repository.