Mind Technology

Creative Solutions for Your Industry

Mind Technology

Creative Solutions for Your Industry

Select your language

Agility

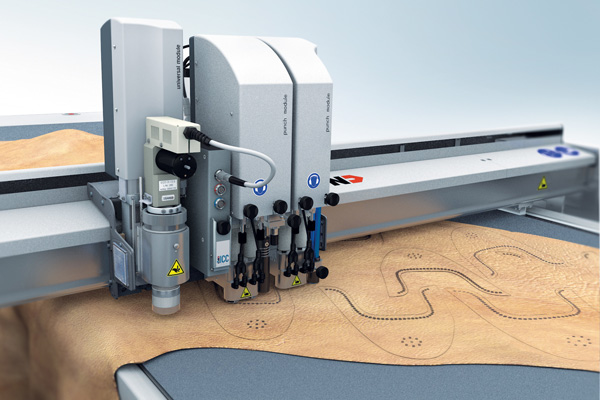

Flexibly define your cutting scenarios and configure your cut cells.

Nest on an unlimited number of materials on large or small tables.

Respond quickly to large or small orders, cut unrestricted standard or customized series of models, leaving the system to optimize and manage the cutting process.

Quality on time

Save the time you now spend on nesting and cutting manually.

Nest the most complex pattern cutting layouts and reduce the time it takes to produce high quality samples or graded patterns.

Cost reduction

Reduce raw material consumption and waste by producing cost effective layouts.

Reuse your existing equipment using the existing interfaces on a wide range of cutting tables.

Studio features

-

Leather digitizing and classification

Digitizing of materials with digital cameras.

Automatic extraction of material contours.

Interactive tools for identification of quality areas and distention directions.

Identification and tracking of leather hides using barcode or RFID labeling systems.

-

Integration

Import of digitized and classified materials.

Import of nestings from MindCUT Automatic Nesting or other third party applications.

Import and definition of cut orders from MindGEST PDM.

-

Process management

Definition of cut orders allowing part-by-part customization.

Definition of nesting restrictions by orientation, margins and material assignment.

Real time information on nesting and cutting efficiency.

-

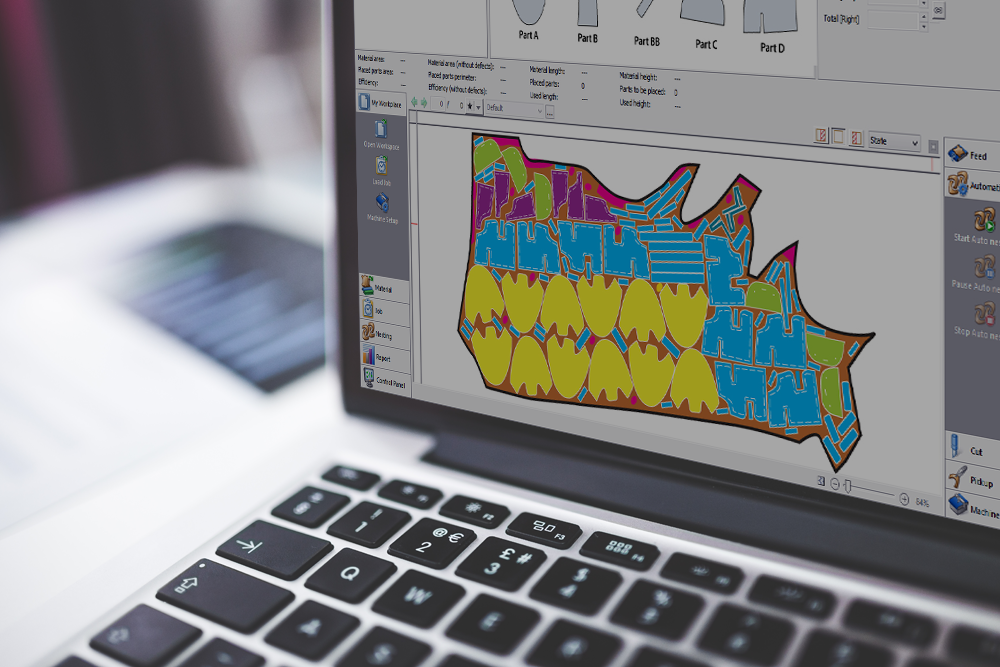

Interactive nesting

Highly optimized intuitive tools for interactive nesting.

Ordering heuristics for part feeding during interactive nesting.

Advanced interactive restrictions based on material and quality rules.

Optimized nested group reuse for interactive and automatic nesting.

-

Cutting optimization

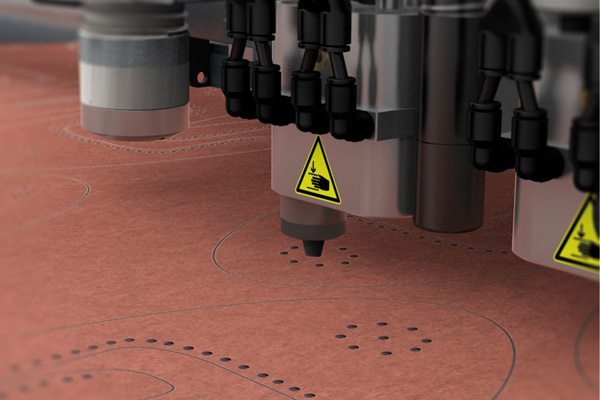

Configuration of the cutting machine tools and cutting path optimizations based on quality requirements, parts geometry, and material type.

Enhanced support for cutting machine operation and control of cutting tools, vacuum cells, conveyors, etc.

-

Parts pickup

Interactive and sequenced collection of parts, using rules based on models, sizes, and job orders.

References and visual aids for parts pickup through direct video projection or printed information.

-

Reporting

Full reporting on digitizing and classification results, nesting efficiency, and cutting performance, with detailed drill-down.