The complete digital solution

The fastest and most reliable way to digitize parts

A flexible and automatic parts digitizer, with features detection, fully integrated with your automated production environment.

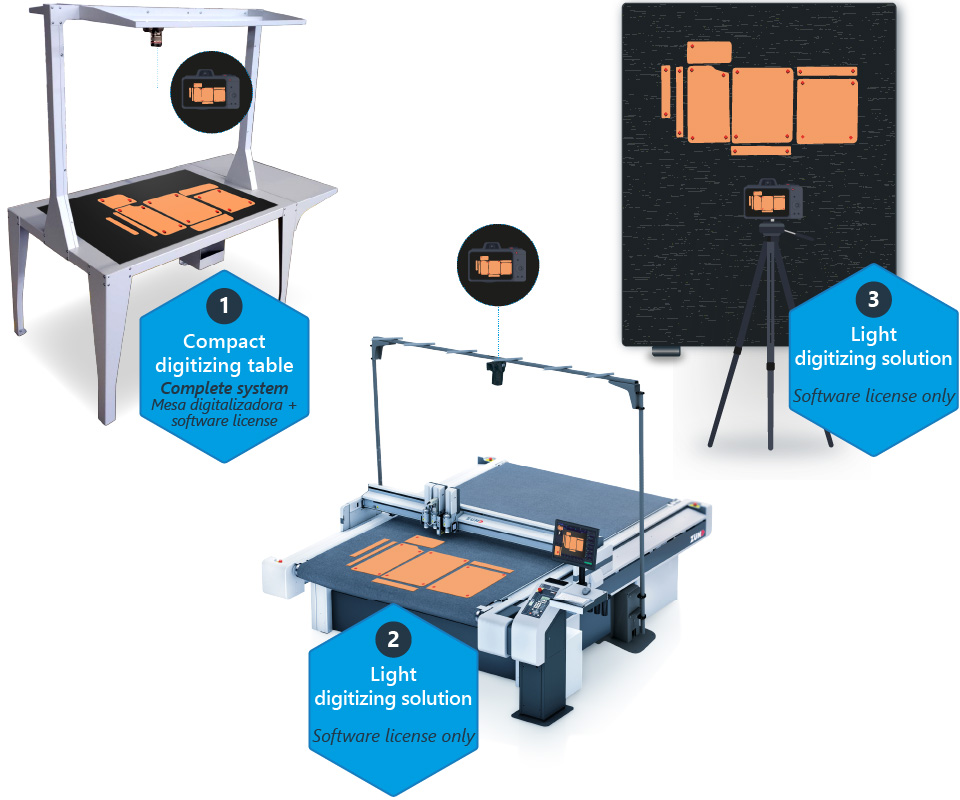

3 WAYS TO ACQUIRE THE SOLUTION

Compact digitizing table

❶ Digitizing table + software

Light digitizing solution (software license)

❷ To be used on a Zünd cutting table with camera

❸ To be used with a wall or desk solution

(camera* mounted on tripod, both not included)

*Canon camera - Specifications supplied on request

The solution

| A digital camera captures the parts and vectorizes boundaries. | The resulting digital data is processed to extract, organize and classify specific features - notches, punches, markings and text. | The features extraction process is flexible and configurable according to a dictionary of shapes and features. | The flexibility of the solution allows you to handle parts of different dimensions, and to capture multiple parts at the same time. The scanned parts can be grouped to form models. | The resulting files are feature-rich, ready to be used in any automatic cutting process. |